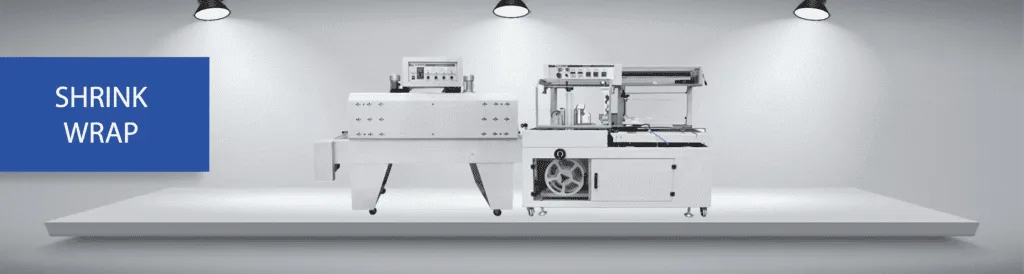

Shrink-wrapping machines are essential tools in various industries, providing an efficient and effective method for packaging products for storage, transportation, and retail. These machines use a film that shrinks tightly around a product when heat is applied, resulting in a secure and professional finish. This article explores the types, applications, and benefits of shrink-wrapping machines.

When selecting a shrink-wrapping machine, consider the following factors:

Shrink-wrapping machines are indispensable in modern packaging processes, offering a versatile, efficient, and cost-effective solution. By understanding the different types of machines and their applications, businesses can select the right equipment to enhance their packaging operations and meet their specific needs.