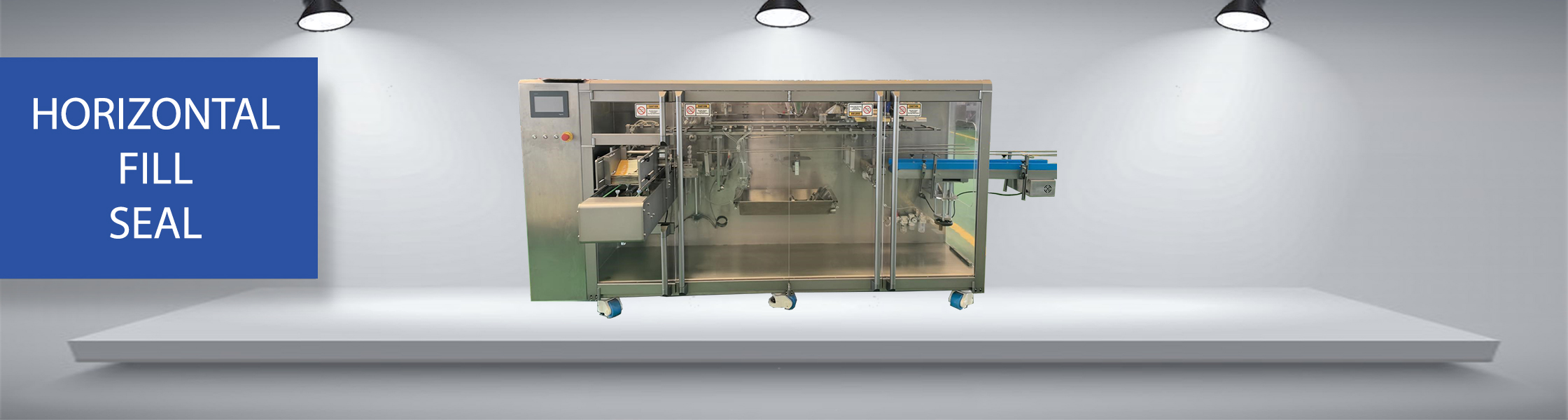

A Horizontal Fill-Seal packaging machine is an automated system that processes pouches horizontally by filling them with product and sealing them in a smooth, continuous operation. It’s widely used for food, beverages, powders, granules, liquids, pastes, and household products because it offers fast output, consistent sealing quality, and a clean, professional finish.

Unlike vertical packaging systems (where product drops down into a bag), a horizontal system moves packaging through the machine on a horizontal track, which is especially useful for pouches and specialty premade bag styles.

Horizontal fill-seal machines typically fall into a few common categories depending on the pack style you’re running. The most popular types are:

A premade pouch packing machine uses ready-made pouches (already formed and cut) that are loaded onto the machine and automatically processed.

Best for:

Stand-up pouches, flat pouches, zipper pouches

Products that need a premium look

Brands that want flexibility across pouch sizes/styles

A sachet packing machine produces small, sealed packets—often used for single-serve portions or samples. Sachets are ideal when you want a compact pack with high output.

Best for:

Powders (coffee, supplements, seasoning)

Liquids (sauces, shampoo, sanitiser)

Granules (sugar, salt)

Samples and single-use products

A doypack is a type of stand-up pouch with a bottom gusset that allows it to stand upright on shelves. A doypack packing machine is designed to run this pouch style efficiently and cleanly.

Best for:

Snacks, nuts, coffee, pet food

Liquids and sauces (with spout options depending on setup)

Premium retail products that need strong shelf presence

Premade pouch machines are used when you want to fill and seal ready-made pouches (often with premium features like zippers).

Common applications include:

Snacks: nuts, crisps, dried fruit, sweets

Powders: protein powder, spices, coffee, supplements

Granules: rice, sugar, salt, pet food

Liquids & sauces: sauces, oils, dressings, beverages (machine configuration dependent)

Household products: detergents, cleaning powders, soaps

Pharma & nutraceutical: tablets, capsules, powdered mixes

Sachet machines are used for small single-serve packs or sample-sized packaging, usually high volume.

Common applications include:

Food & drink: ketchup/mayo sachets, sugar sticks, instant coffee, seasoning

Powders: electrolyte sachets, collagen, vitamins, drink mixes

Liquids & gels: sauces, honey, syrups, sanitiser, lubricants

Cosmetics & personal care: shampoo, conditioner, lotions, face masks

Pharmaceutical samples: creams, gels, powders, single-dose products

Doypack machines are designed for stand-up pouches (bottom gusset) for strong shelf presentation.

Common applications include:

Snack & retail foods: nuts, granola, popcorn, dried fruit, confectionery

Coffee & tea: coffee beans/grounds, loose tea

Pet food: treats and dry pet food

Powders: supplements, drink mixes, baking powders

Liquids & sauces: sauces, soups, ready-to-drink products (with the right fill + pouch)

Frozen or chilled products: depending on film type and sealing requirements

Horizontal Fill-Seal packaging machines are widely used because they offer a reliable way to package many product types in pouch formats, with consistent results and strong presentation.

Horizontal systems are ideal for pouch-style packaging, producing clean, consistent packs that look great for retail and e-commerce.

Depending on the filling system, Horizontal Fill-Seal Packaging machines can handle:

Powders (coffee, spices, protein)

Granules (rice, sugar, salt)

Liquids (sauces, drinks, detergents)

Pastes & gels (creams, condiments)

Solid products (snacks, confectionery, hardware)

These machines are built to deliver repeatable seals for freshness and leak prevention, helping reduce waste and improve pack integrity.

HFS machines automate the key steps of packaging—feeding/forming, opening, filling, and sealing—so production can run faster and more consistently than manual packing.

Horizontal machines can support a range of pouch styles depending on configuration, including:

Premade pouches

Sachets

Doypacks (stand-up pouches)

Optional formats like zippers, tear notches, and gussets (machine + pouch dependent)

HFS lines can be integrated with equipment such as:

Date/batch coding

Checkweighers

Metal detection / X-ray

Conveyors and collection tables

Nitrogen flushing (for shelf-life, if required)

Because the process is automated, it can reduce reliance on manual packing while keeping output and pack quality consistent across shifts.

Most horizontal fill-seal setups follow the same basic steps:

Pouch is fed or formed (depending on machine type)

The pouch is opened and held in place

Product is filled (liquid, powder, granule, paste, etc.)

Air is removed, or gas is flushed (optional, for shelf-life)

Top is sealed (heat seal / ultrasonic, depending on material)

Finished pack is discharged (ready for boxing or cartoning)

A Horizontal Fill and Seal (HFS) machine is an automated packaging system that fills and seals pre-formed packaging such as pouches, trays, or blisters. Unlike HFFS machines, HFS machines do not form the packaging from rollstock film.

HFS machines work with pre-made packaging, including:

Pre-formed pouches

Trays

Blister packs

Sachets supplied in finished form

This makes HFS machines ideal for premium or complex packaging formats.

HFS machines can package a wide range of products, including:

Food products (ready meals, sauces, snacks)

Pharmaceuticals and medical devices

Cosmetics and personal care items

Chemicals and industrial components

The filling system is selected based on product consistency and dosing accuracy.

The key difference is the forming stage:

HFS machines fill and seal pre-formed packaging

HFFS machines form the packaging from rollstock, then fill and seal it

HFS machines offer greater flexibility in pack design but typically have higher packaging material costs.

Production speed depends on the product, pack type, and filling system. Most Horizontal Fill and Seal machines operate at medium speeds, typically 20 to 120 packs per minute.

Yes. HFS machines can be fitted with:

Piston fillers

Peristaltic pumps

Volumetric or servo-driven dosing systems

This allows accurate filling of liquids, gels, creams, and viscous products.

Yes. HFS machines for food and pharmaceutical use are manufactured using hygienic, food-grade materials and can comply with HACCP and GMP requirements, depending on the configuration.

HFS machines are highly flexible and ideal for:

Multiple pack sizes

Frequent changeovers

Short to medium production runs

Premium packaging formats

Changeovers are generally faster compared to form-fill-seal machines.

Depending on the packaging material, HFS machines can use:

Heat sealing

Ultrasonic sealing

Induction sealing

The sealing method is selected based on product protection and shelf-life requirements.

Typical requirements include:

Industrial electrical supply (380–415V, 3-phase)

Compressed air for pneumatic functions

Exact specifications depend on machine size and options.

Yes. Horizontal Fill and Seal machines can integrate with:

Infeed and outfeed conveyors

Tray denesters

Checkweighers

Metal detectors

Cartoning and case packing systems

Routine maintenance includes:

Cleaning sealing and filling components

Inspecting seals and sensors

Lubricating moving parts

Replacing wear components as required

Regular maintenance ensures consistent sealing quality and reduced downtime.

HFS machines are widely used in:

Food processing and ready meals

Pharmaceutical and medical packaging

Cosmetics and personal care manufacturing

Chemical and industrial packaging

Yes. HFS machines are typically supplied with local installation, commissioning, and operator training to ensure safe and efficient operation.

The correct HFS machine depends on:

Type of pre-formed packaging

Product characteristics

Required production speed

Hygiene requirements

Future scalability

A consultation with a local packaging machinery specialist is recommended.