Shrink wrap for beverage multipacks play a critical role in modern beverage packaging operations, especially for manufacturers and bottlers looking to improve efficiency, consistency, and shelf-ready presentation. In South Africa’s highly competitive beverage market, reliable shrink wrapping solutions are essential for handling bottled water, soft drinks, energy drinks, juices, and canned beverages at scale.

Whether you are packaging 6-packs, 12-packs, or custom promotional bundles, shrink wrap technology offers a cost-effective and durable solution that supports both retail and distribution requirements.

Beverage multipacks require packaging that is strong, stable, and visually appealing while still being economical. Shrink wrap machines meet these demands by tightly sealing plastic film around grouped products, creating a secure pack that resists movement during transport.

Key benefits include:

High packaging speed for medium to high-volume beverage lines

Improved load stability for bottles and cans

Reduced packaging material costs compared to cartons

Clear product visibility for retail shelves

Compatibility with promotional and seasonal multipacks

For beverage producers operating across South Africa, shrink wrapping also helps ensure packs arrive intact at retailers, distributors, and wholesalers nationwide.

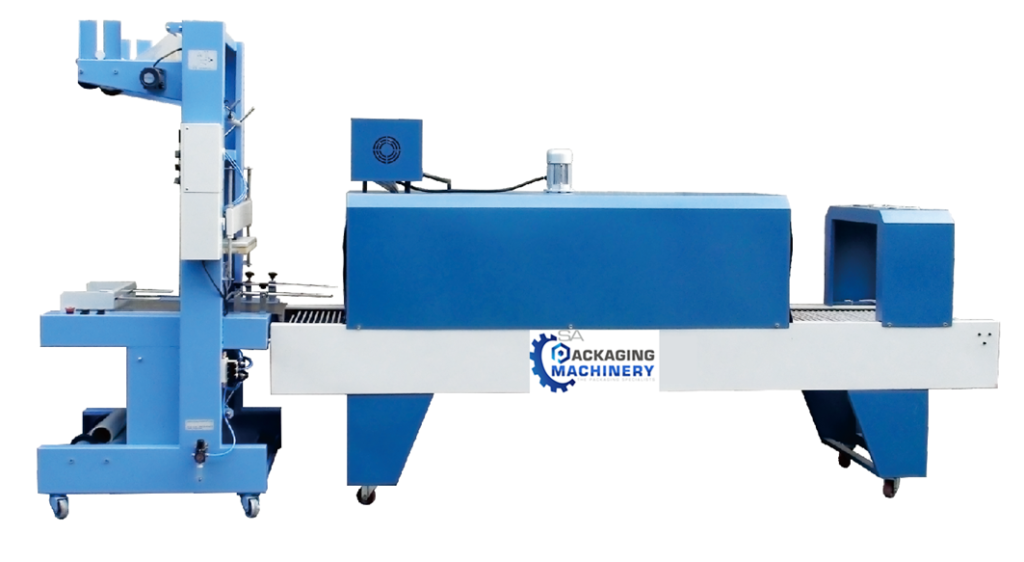

Automatic systems are ideal for large beverage producers requiring continuous, high-speed output. These machines integrate seamlessly with conveyors and filling lines, handling consistent multipack sizes with minimal manual intervention.

Shrink wrap for beverage multipacks in this category are commonly used for:

Bottled water multipacks

Carbonated soft drink trays

Canned beverage bundles

Semi-automatic machines offer flexibility for smaller beverage manufacturers or businesses with varied pack configurations. Operators manually load products, while the machine handles sealing and shrinking.

This option is popular among:

Craft beverage producers

Regional juice manufacturers

Small-to-medium bottling plants

One of the biggest advantages of shrink wrap for beverage multipacks is their versatility. The same system can often be configured to handle:

PET bottles

Glass bottles (with tray support)

Aluminium cans

Mixed beverage promotional packs

Using shrink film ensures that multipacks remain tightly bound, reducing the risk of product separation during handling and transportation.

When selecting a shrink wrap solution, South African beverage manufacturers should consider:

Production volume requirements

Type of beverage containers

Available floor space

Energy efficiency and operating costs

Local technical support and spare parts availability

Working with a local packaging machinery supplier ensures faster support, easier servicing, and machinery suited to local operating condition

Shrink wrap packaging reduces excess materials while still providing strong protection. Many modern shrink wrap machines support thinner, recyclable films, helping beverage brands improve sustainability without compromising performance.

Lower material usage also means:

Reduced packaging waste

Lower transport costs

Improved carbon footprint

Looking for reliable shrink wrap machines for beverage multipacks in South Africa?

Our team at SA Packaging Machinery supplies robust, industry-proven shrink wrapping solutions designed for beverage manufacturers of all sizes.

📞 Contact us today to discuss your production requirements, request a quote, or arrange a consultation with our packaging machinery specialists.

Shrink wrap machines can package bottled water, soft drinks, juices, energy drinks, and canned beverages in various multipack formats.

Yes. Automatic shrink wrap machines are specifically designed for high-volume beverage production environments.

Yes. Many beverage multipacks use trays combined with shrink film for added strength, especially for glass bottles.

Yes. SA Packaging Machinery supplies and supports shrink wrap machines for beverage multipacks locally.

Most shrink films are recyclable, and modern machines support thinner, eco-friendly film options.