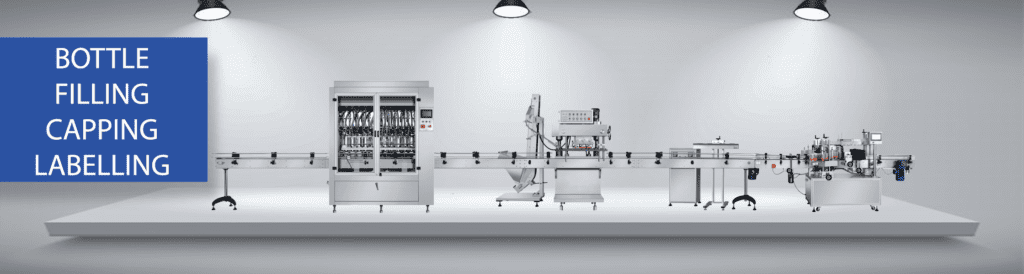

In today’s competitive manufacturing landscape, an automatic bottling line is essential for ensuring consistency, speed, and hygiene in liquid filling operations. From water, juice, and oils to detergents and pharmaceutical liquids, a well-configured linear liquid bottling line integrates the liquid filling machine, capping system, and labelling unit to turn bulk product into shelf-ready bottles with minimal human intervention.

Below, we break down the key components of a linear bottling line and how each contributes to efficient, high-quality production.

The liquid filling machine is the core of any bottling line. In a linear setup, bottles move in a straight line through the filler, where product is dispensed accurately into each container. The number of filling heads impacts both production speed and suitability for different liquid types:

2-Head and 4-Head FillersIdeal for smaller operations or thicker liquids like sauces, creams, or oils. Slower filling ensures precision and prevents splashing.. |

6-Head and 8-Head FillersDesigned for medium-capacity production lines handling beverages, detergents, or lubricants. These provide a balance between speed and accuracy. |

10-Head and 12-Head Fillers (and beyond)Perfect for high-speed applications, often exceeding several thousand bottles per hour. Best suited for water, juice, and thin liquids that fill quickly without foaming or dripping. |

Depending on the product characteristics, different filling principles are employed:

Piston FillersIdeal for viscous or semi-viscous liquids such as creams, gels, sauces, and pastes. These fillers use a precise volumetric piston action to deliver consistent fills with excellent accuracy. |

Gravity or Overflow FillersBest suited for thin, water-like products that require level accuracy. Gravity or overflow fillers ensure each bottle is filled to the same visible level, ideal for beverages, cleaning liquids, and solvents. |

Pump Fillers (Lobe or Peristaltic Pumps)Used for hygienic and controlled dispensing, often in food, cosmetic, and pharmaceutical industries. These systems offer precise flow control and are easy to clean, making them perfect for sensitive or high-value liquids. |

Choosing the right filler configuration ensures efficiency, minimizes waste, and maintains consistent product quality.

After filling, bottles move to the capping machine, where caps are automatically applied and tightened or sealed. Capping varies depending on the cap type and bottle design, making adjustable or interchangeable capping heads essential.

| Cap Type | Typical Applications | Capping Head Description |

|---|---|---|

| Screw Caps | Beverages, detergents, and cosmetics | Require torque-controlled heads to prevent over-tightening and ensure a secure seal. |

| Press-On or Snap Caps | Dairy, sauces, and condiments | Heads apply downward pressure to securely press the cap into place. |

| Ropp or Aluminum Caps | Pharmaceuticals and spirits | Require rolling-type heads to crimp the aluminum caps neatly around the bottle neck. |

| Pump or Trigger Caps | Cleaning products and personal care items | Specialized chuck-style heads accommodate extended stems and irregular shapes. |

Advanced cappers often feature vibratory or rotary cap feeders to automatically orient and feed caps, ensuring continuous operation and a leak-proof, tamper-evident seal that preserves product integrity.

The final stage in a linear liquid bottling line is the labelling machine, which applies labels accurately as bottles exit the capping station. Labelling is critical for brand presentation, compliance, and traceability.

Modern labellers integrate photoelectric sensors and servo-driven controls to maintain precision even at high speeds. Many also include date-coding or batch printing units to add expiry dates or traceability information seamlessly.

When combined, the liquid filling machine, capping, and labelling systems form a fully automatic bottling line that reduces downtime, minimizes human error, and ensures consistent output. Each component can be tailored to match production speed, bottle size, and liquid type, making the system adaptable to a variety of industries.

To see a linear liquid bottling line in action, watch this video demonstration of a bottle filling line.

From small-scale producers to large manufacturing plants, an automatic bottling line enhances product quality, improves operational efficiency, and supports future scalability.

A well-designed liquid filling line combines precision engineering with intelligent automation to handle liquids ranging from thin beverages to viscous creams. With the right configuration of filling heads, capping systems, and labelling machines, manufacturers can achieve faster production, lower costs, and a professional finish. Whether packaging beverages, chemicals, or cosmetics, an automatic linear liquid bottling line ensures every bottle is filled accurately, sealed securely, and labelled perfectly — ready for the shelf.

At SA Packaging Machinery, we supply high-quality liquid filling lines designed to optimize your packaging line. Our systems are durable, easy to use, and customizable to suit different production scales. Whether you’re packaging small batches or high-volume multi-packs, we’ll help you find the right machine for your promotional goals.

Ready to take your liquid filling line to the next level?

📞 Get in touch with us today!

Our expert team is here to help you choose the perfect liquid filling line to fit your production needs.