When comparing Automatic vs Manual Liquid Filling Machines, many manufacturers wonder which option offers the best balance of speed, accuracy, cost, and long-term value. Choosing the right liquid filling system has a direct impact on your production efficiency and overall operational costs. In this article, we break down the key differences, advantages, and disadvantages, helping you make an informed decision for your business.

Liquid filling machines are essential in industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, detergents, and household products. Whether you run a small startup or a large manufacturing facility, your choice between Automatic vs Manual Liquid Filling Machines will influence your productivity and bottom line.

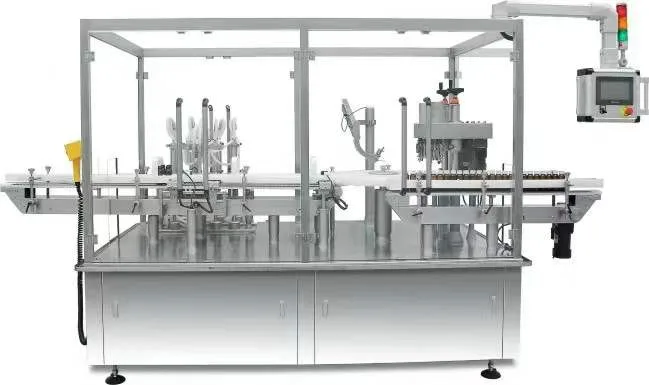

Automatic liquid fillers are designed to offer maximum efficiency and consistency. These machines are ideal for medium to high-volume production environments.

Automatic machines can fill hundreds — even thousands — of bottles per hour. This makes them perfect for growing companies that need to meet large order quantities.

Automated fillers minimize human error. With precise dosing technology, they ensure consistent fill volumes, reduced spillage, and improved product quality.

Although automatic machines have a higher upfront cost, they save money long term by reducing the number of operators needed on the production line.

Automatic fillers can be paired with conveyors, capping machines, labellers, inkjet coders, and sealing equipment — creating a streamlined packaging workflow.

Manual liquid fillers are often used by small businesses, startups, and low-volume manufacturers.

These machines are much more affordable and perfect for companies just starting out with limited budgets.

Manual machines require minimal training and are easy to clean, maintain, and repair.

If your production demand is low or you manufacture small batches of specialty liquids, manual filling systems can be sufficient.

Some manual piston or lever-based fillers can handle thicker products more effectively without needing advanced automation.

Automatic: Very high output, perfect for scaling.

Manual: Slow, best for micro or boutique manufacturing.

Automatic: Highly precise dosing.

Manual: Accuracy depends on operator skill.

Automatic: Higher initial cost, lower long-term labour costs.

Manual: Cheaper upfront, but labour adds up as production grows.

Automatic: Easily scalable with additional accessories.

Manual: Limited by physical labour and manual operation.

When deciding between Automatic vs Manual Liquid Filling Machines, consider the following:

Your production volume

Your budget

Your product viscosity

Future scalability

Required accuracy

Labour availability

If you are planning to expand and want consistent, fast production — automatic is the better choice. For low-volume or startup operations — manual is more cost-effective.

Looking for the right filling machine for your product?

SA Packaging Machinery supplies high-quality manual, semi-automatic, and fully automatic liquid filling systems to suit all production sizes. Our team will help you choose the perfect filling solution for your production needs.

Automatic is better for high-volume production, while manual is suitable for low-volume or startup environments.

Yes. They require fewer operators, reducing long-term labour expenses.

Yes, manual piston fillers often handle viscous liquids very well.

Not necessarily. They require scheduled maintenance, but modern systems are user-friendly and reliable.

Absolutely. Many businesses start with manual machines and upgrade as demand grows.