What is a Horizontal flow wrap machine? They are highly efficient packaging machines that seal products horizontally with clear or printed PET/PE, or BOPP-based film, making them ideal for packing large quantities of individual products.

Our flow wrap machines are suitable for many applications and can be customised according to your production needs.

Flow wrap machines are purpose-built machines that can use punnets and trays for the flow wrapping of goods in many industries. Products like fresh produce, pastries, bakery goods, confectionery, consumer goods like scratch cards, stationery, and magazines, and household goods like napkins and disposable cutlery can be flow-wrapped to protect against damage. Additional gas flushing can replace oxygen with nitrogen inside the packaging to preserve goods’ shelf life.

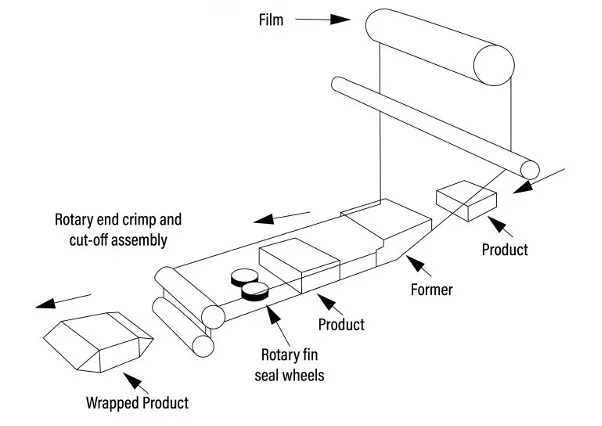

A flow wrapping machine, also known as a horizontal flow wrapper, is a packaging machine designed to wrap products in a continuous flow of material. This type of machine is widely used in various industries, including food, pharmaceuticals, and consumer goods, to package items quickly and efficiently. Here’s how it works and its main components:

Flow wrap machines seal products inside a neat pillow-shaped film or foil package to improve shelf life and guard against contamination. Typically, an infeed conveyor belt transports goods into a forming box that forms a continuous film tube around products. Next, a rotary heat sealer and cutter will separate and crimp seal goods to form individually packaged products that are primarily rectangular or square-shaped with a horizontal back seal and top and bottom vertical seals.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.