In today’s fast-paced cosmetic and personal care industry, precision, efficiency, and reliability in packaging are more critical than ever. Manufacturers require advanced solutions to keep up with increasing demand while maintaining strict quality standards. This is where liquid filling technology comes into play. Designed to handle creams, lotions, and other viscous products, modern liquid filling systems offer unparalleled automation, consistency, and speed, making them indispensable for cosmetic and personal care production.

With consumer expectations rising for both product quality and packaging appearance, an efficient liquid filling line is no longer optional—it’s essential. Automated systems allow manufacturers to produce large quantities without sacrificing accuracy, helping brands maintain a competitive edge in the market.

A fully automated liquid filling line is a game-changer for any manufacturer looking to enhance productivity and ensure product integrity. These integrated systems combine multiple machines into a single streamlined process, reducing the need for manual labor and minimizing the risk of errors.

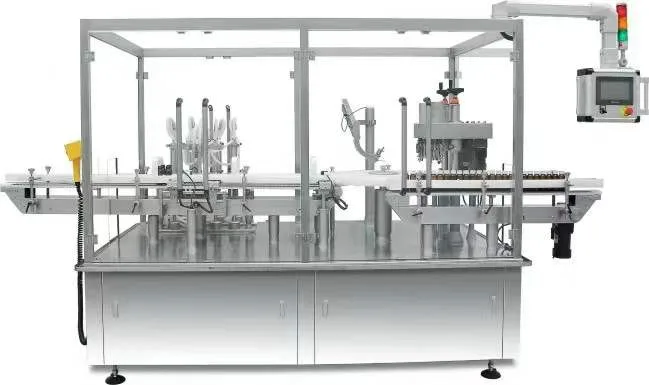

For example, a bottling line specifically designed for creams and lotions features a Monoblock 4-Head Filler & Dual Capper, which precisely fills bottles and securely applies both inner and outer caps. This ensures tamper-proof packaging, essential for maintaining consumer trust and compliance with industry regulations.

Beyond filling and capping, a modern line can include features like adjustable fill volumes, programmable dosing for different product viscosities, and automated cleaning cycles to maintain hygiene—critical for cosmetic and personal care products.

Modern liquid filling lines incorporate several machines to maintain a smooth workflow:

Key components of a liquid filling line:

Transfers bottles to the next stage without interruption, preventing bottlenecks.

Confirms that each bottle meets exact weight requirements, improving quality control and reducing waste.

Applies front and back labels with perfect alignment for a professional, premium appearance.

Automatically checks label accuracy, batch numbers, and traceability information for regulatory compliance.

Collects finished bottles neatly for downstream packing and logistics, ensuring efficient workflow.

By combining all these machines into a single line, manufacturers can significantly increase throughput, reduce labor costs, and maintain consistent product quality.

Liquid filling systems are especially suited for the cosmetic and personal care sectors, where product viscosity and sensitivity require precise handling. From lightweight skincare lotions to dense creams, these machines are engineered to handle a wide range of textures without compromising speed or accuracy.

Key benefits include:

Investing in a modern liquid filling line helps cosmetic and personal care brands compete effectively while reducing waste, minimizing errors, and improving overall productivity.

For more information on how modern cosmetic bottling solutions can optimize your production line, check out this comprehensive guide on cosmetic filling and packaging equipment. This resource covers best practices, machine types, and innovative techniques for achieving high-quality, consistent packaging.

Whether you are upgrading an existing line or building a new production facility, understanding the latest trends and technology in cosmetic bottling is essential for staying ahead in the industry.

If you’re ready to upgrade your production line, contact us today to discuss your liquid filling needs. Our experts can help you select the right machines, customize your bottling line, and ensure seamless integration for creams, lotions, and other personal care products. With our support, you can increase efficiency, maintain compliance, and deliver products that meet the highest quality standards.