Choosing the right equipment is essential for maintaining efficiency and consistency in your production line, and one of the biggest decisions manufacturers face is selecting between manual vs automatic filling machines. Whether you are filling liquids, powders, pastes, or granules, understanding the differences between these two machine types can help you make the best investment for your business. In this guide, we break down how each system works, the pros and cons, and which option is best for your current and future production needs.

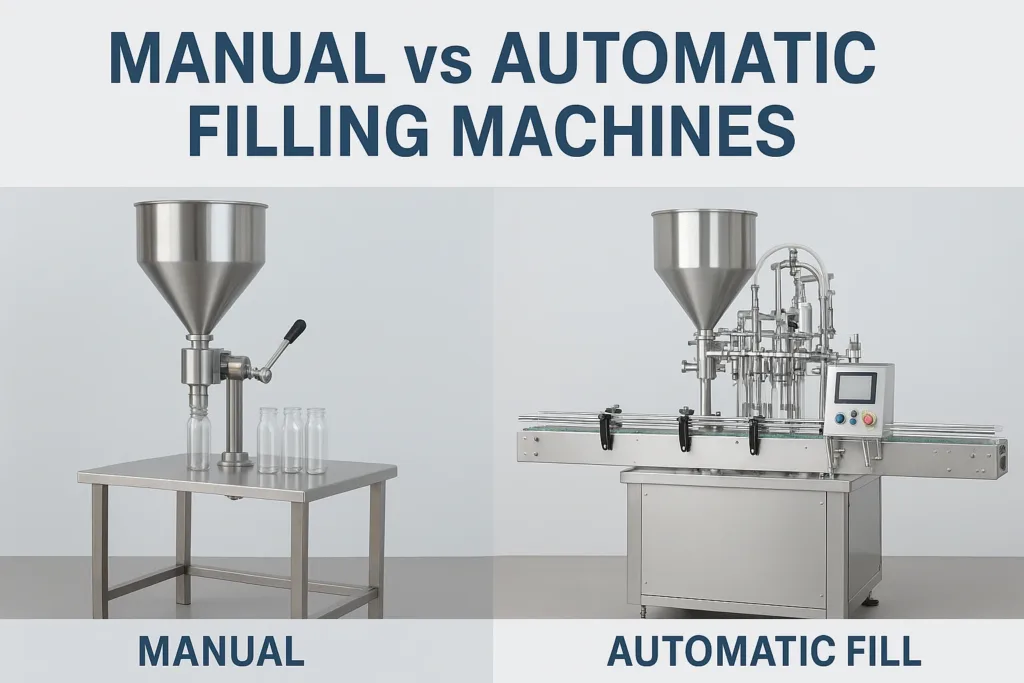

Manual vs automatic filling machines differ mainly in their level of automation, speed, and operator involvement. Manual filling machines rely heavily on human operation to control the filling process, while automatic filling machines are designed to streamline production with minimal manual input. Both have unique advantages that suit different business sizes and production requirements.

Manual filling machines are often the go-to choice for small businesses or start-ups with low to medium production volumes. They are affordable, easy to operate, and require minimal maintenance. Because they allow operators to control the filling process manually, they are ideal for small batch products, craft manufacturers, or businesses that frequently switch between product types.

Automatic filling machines, on the other hand, offer unmatched consistency and speed. For brands looking to scale quickly, automatic machines reduce labour costs, minimise product waste, and increase output significantly. This is especially valuable in industries requiring precision, such as pharmaceuticals, cosmetics, food and beverage, and chemicals.

When comparing manual vs automatic filling machines, speed is the most noticeable difference. A manual filler may output a few hundred units per hour, depending on the operator. Automatic filling machines, however, can fill thousands of units in the same time frame without fatigue or human error.

Manual Machines:

Operator-controlled filling

Slower production speed

Suitable for small batches

Low cost and simplicity

Automatic Machines:

High-speed production

Consistent filling volumes

Multiple filling heads for greater output

Seamless integration with conveyors and packaging systems

If your business is experiencing growing demand, this difference in efficiency becomes a major factor in deciding which machine is right for you.

Cost plays a major role when purchasing filling equipment. Manual machines generally require a much lower upfront investment. They are ideal for businesses needing simple, straightforward equipment without major automation.

Automatic filling machines come with a higher initial cost but offer long-term savings through reduced labour, lower product wastage, and higher production output. Over time, these machines often pay for themselves by increasing profitability and improving production efficiency.

Accuracy is essential in industries that require consistent fill levels, such as cosmetics, pharmaceuticals, and food manufacturing. Manual machines allow flexibility, but accuracy depends on the operator’s skill and attention.

Automatic machines use advanced sensors, control systems, and sometimes servo motors to achieve highly accurate fill levels. This reduces waste and ensures product quality remains consistent, especially for brands that must comply with industry regulations.

Choosing between manual vs automatic filling machines depends on four key factors:

Low output → Manual

Medium to high output → Automatic

Low starting cost → Manual

Long-term cost efficiency → Automatic

Frequent changes and small batches → Manual

Consistent, high-speed filling → Automatic

Staying small or niche → Manual

Planning to scale → Automatic

If your business is growing or you expect to increase production in the next 1–3 years, an automatic filling machine is often the smarter investment.

Looking for expert guidance on manual vs automatic filling machines? Our team can help you choose the best machine for your packaging and production needs.