Premade pouches have revolutionized packaging. These ready-to-use bags are designed for convenience, speed, and product appeal. Unlike traditional packaging, premade pouches come fully formed, requiring only the filling of the product. This innovation speeds up the packaging process and offers greater flexibility, making it suitable for various products across different industries.

In this article, we will explore the key features, benefits, and considerations of premade pouches. We will also discuss the latest trends in the packaging industry and how this packaging method is meeting consumer demand.

Premade pouches are pre-manufactured packaging solutions that come ready to be filled with the desired product. Unlike form-fill-seal pouches, which are created, filled, and sealed in one continuous process, premade pouches are made beforehand by flexible packaging converters. This method allows for faster production and greater customization. They are commonly used in food, beverage, cosmetic, and pharmaceutical industries, offering a quick and efficient packaging solution.

Furthermore, premade pouches are designed to offer more than just functionality. Their unique designs provide convenience, portability, and enhanced consumer appeal, making them an ideal choice for many brands.

Premade pouches differ significantly from form-fill-seal (F/F/S) pouches. In the case of F/F/S pouches, the material is unrolled, formed into a pouch, filled with the product, and sealed in a continuous process. This method requires specialized machinery and more time for setup.

On the other hand, premade pouches are delivered fully formed, eliminating the need for extensive machinery setup. Therefore, they offer faster turnaround times and are often more cost-effective for smaller production runs. However, for larger-scale operations, F/F/S pouches may provide greater flexibility in terms of customization and production efficiency.

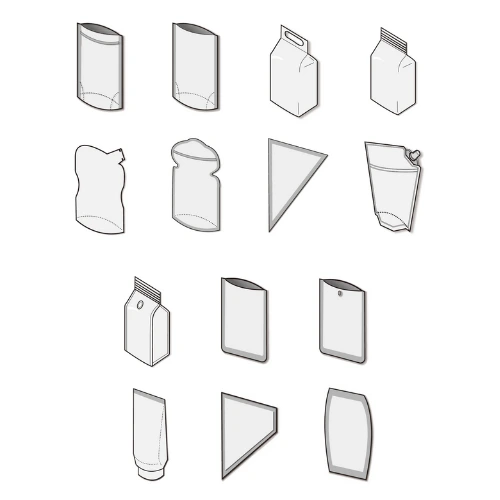

Premade pouches offer several design features that enhance both functionality and branding. Common features include resealable zippers, spouts for liquids, clear windows for product visibility, and unique shapes that are not possible with rigid packaging. These innovations make the packaging more user-friendly and help attract consumers.

In addition, premade pouches can be customized to suit specific product requirements. Manufacturers can choose the size, material, and design elements, such as vibrant graphics, to align with brand identity. For example, digital printing allows for intricate and colourful designs that make products stand out on the shelves.

These design options not only appeal to consumers but also provide brands with a powerful marketing tool. Packaging that is visually appealing can help increase product visibility and consumer engagement.

The materials used in premade pouches are critical for protecting the contents from external factors such as moisture, light, and air. Common materials used for premade pouches include polyethylene, polypropylene, aluminum foil, and biodegradable options. Each material has its unique properties that contribute to the preservation of the product.

For instance, aluminum foil provides a robust barrier against light and oxygen, making it ideal for packaging products sensitive to these elements. Meanwhile, biodegradable materials offer an eco-friendly alternative for brands aiming to reduce their environmental impact.

Therefore, selecting the appropriate material is crucial to ensure the freshness and safety of the product throughout its shelf life. Additionally, the right material choice helps improve the sustainability of the packaging solution.

The rise in demand for premade pouches is largely driven by changing consumer preferences. More and more consumers prefer products that are convenient, easy to store, and portable. Premade pouches meet these needs by offering lightweight packaging that is easy to open, reseal, and store.

Moreover, there is growing consumer demand for sustainable packaging solutions. Many premade pouches are now made from recyclable or compostable materials, which aligns with the values of environmentally conscious shoppers. Additionally, the smaller size and lighter weight of pouches make them more energy-efficient to transport, further reducing their environmental impact.

These shifts in consumer preferences have made premade pouches an increasingly popular choice for manufacturers looking to meet both practical and environmental demands.

Premade pouches can be a more sustainable packaging option compared to traditional materials. Their lighter weight and smaller size reduce material usage, which in turn lowers transportation costs and greenhouse gas emissions. Additionally, many manufacturers are turning to biodegradable and recyclable materials to produce these pouches, helping to reduce plastic waste.

Brands that prioritize sustainability are choosing eco-friendly premade pouches to align with consumer expectations and contribute to a greener future. By opting for biodegradable films or compostable materials, manufacturers can further reduce their environmental footprint.

In short, premade pouches offer a sustainable packaging option that balances consumer demand for convenience with eco-friendly practices.

Choosing the right supplier for premade pouches is essential for ensuring the success of your packaging strategy. Here are some factors to consider:

By carefully considering these factors, you can select a supplier who aligns with your packaging needs and ensures high-quality results.

To ensure that premade pouches meet all performance standards, manufacturers use rigorous quality assurance processes. These include:

These quality control measures help ensure that each pouch is durable, safe, and performs as expected, maintaining the product’s integrity throughout its lifecycle.

The future of premade pouch packaging looks promising, with several exciting trends on the horizon:

These innovations will shape the future of premade pouch packaging, ensuring it remains at the forefront of the packaging industry.

Premade pouches have become a key player in the packaging industry. Their speed, convenience, and design flexibility make them ideal for a wide range of products. With increasing consumer demand for sustainable, user-friendly, and customizable packaging, premade pouches will continue to grow in popularity. As technology advances, they will remain a central part of the packaging industry, offering new possibilities for brands and consumers alike. Contact us today to learn more about our premade pouch packaging solutions and discover how we can help you enhance efficiency, meet sustainability goals, and create packaging that stands out in the market.

Premade pouches are pre-formed bags used for packaging. These pouches come ready to be filled, which saves time in the production process. They are available in various designs, materials, and sizes.

The material choice plays a critical role in the pouch’s durability and product protection. Materials like polyethylene and aluminum foil provide excellent barrier properties, while biodegradable options are becoming increasingly popular for eco-conscious brands.

Premade pouches can feature resealable zippers, spouts, clear windows, and custom shapes. These features not only make the packaging more functional but also enhance branding and consumer appeal.

Premade pouches use fewer materials compared to rigid packaging, which reduces waste and carbon emissions. Many are also made from recyclable or compostable materials, making them a more eco-friendly option.

When selecting a supplier, consider their production capabilities, customization options, sustainability practices, and quality assurance measures. A good supplier should meet your packaging needs efficiently while adhering to high standards.

The future of premade pouches will focus on sustainable materials, smart packaging technologies, increased customization, and automation. These trends will drive innovation and make premade pouches even more versatile and consumer-friendly.